About US

From a humble start in the midst of the 1980s recession with two employees and having to literally mortgage the family farm, a seed was planted. That seed now has grown to a multi-million-dollar corporation of 160 associates.

All American Steel ™ today manufactures and provides metal building products and services used in residential, agricultural and commercial markets; committed to manufacturing high-quality products; making sure that product gets to the job site on time and in the same condition it was produced.

All American Steel loves to manufacture steel panels for agricultural, residential, and commercial use. We have steel in our blood, and in our quest, to give our customers the very best products. Of course it is…. but every manufacturer says that, right? How about we back that up? Let’s talk turkey…..ok, well, maybe Steel instead.

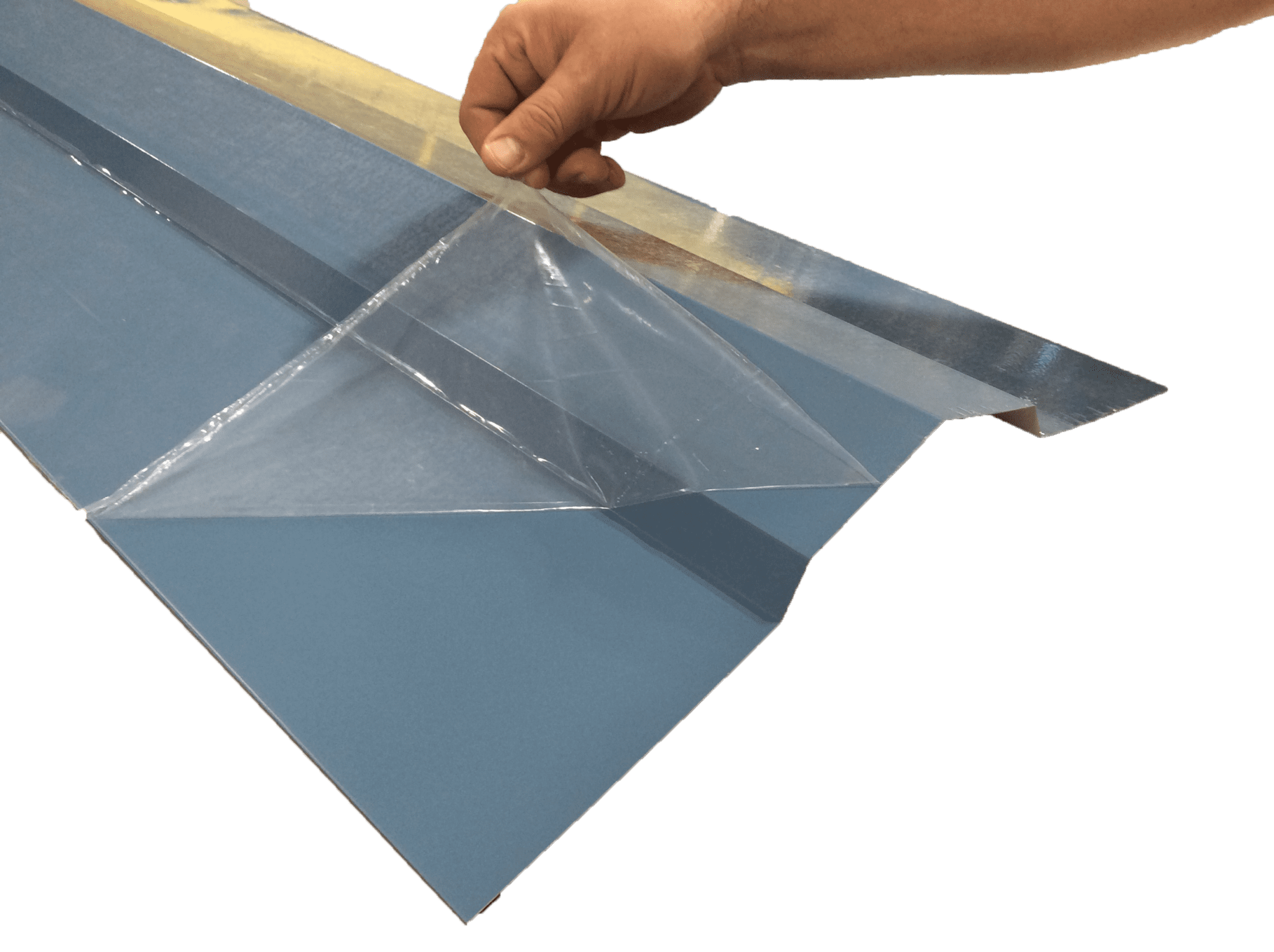

- All American Steel puts a film on all of its smooth trim. It costs a considerable amount of money to do so, but every piece of trim comes to you in factory shape every job, every time. Very few manufacturers in the nation make an effort to do this; it is who we are; it is about our culture.

- The ends of all our exposed fastener panels are treated with a rust inhibitor, on both ends. Some manufacturers treat only one because it is difficult to do both ends with multiple length panels all in the same job lot. We have figured how to do it, and we are not telling how; it is our gift to our customers.

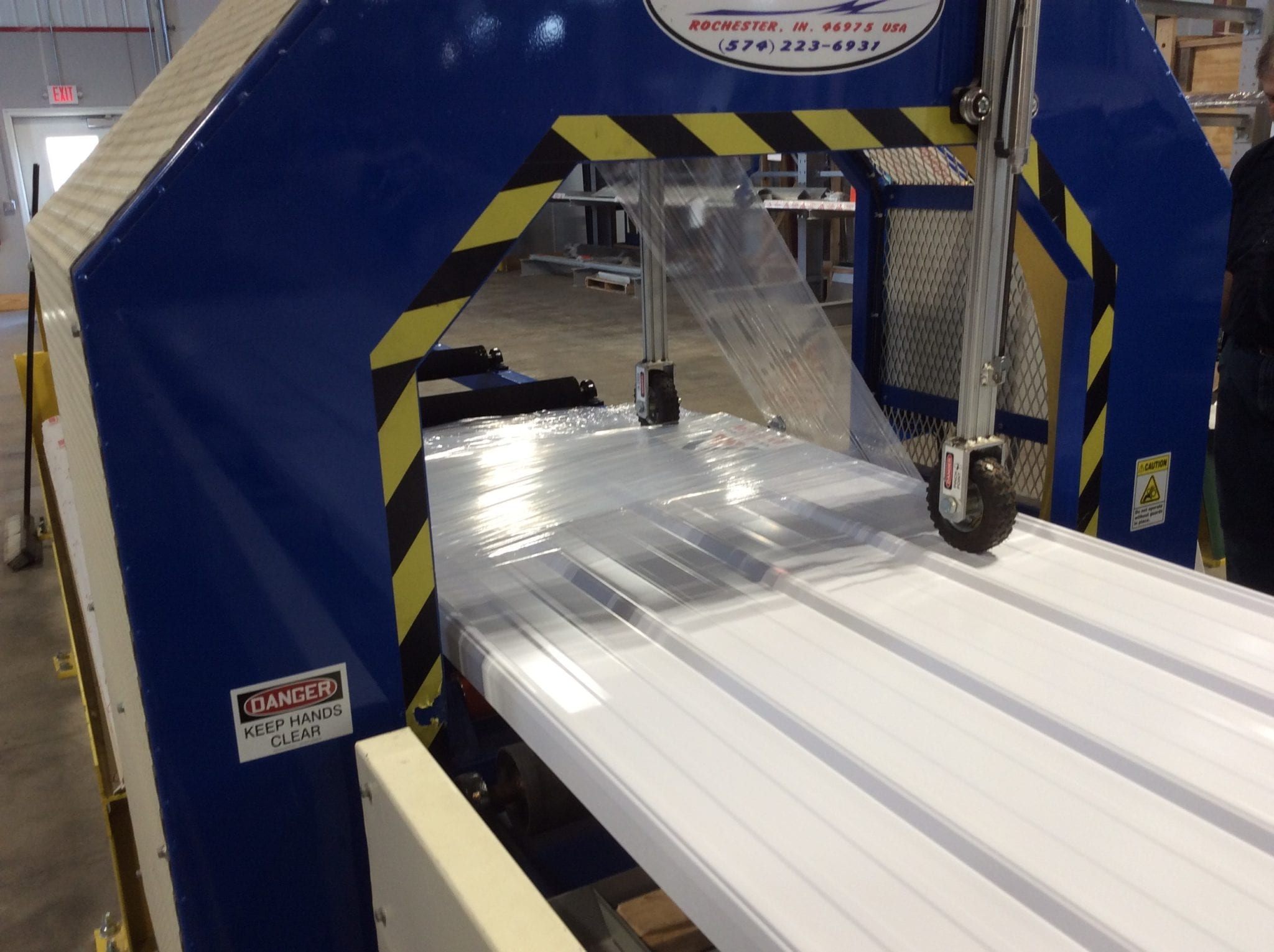

- We shrink-wrap our panels. Again, not many manufactures do that. For All American Steel, it is all about getting our panels to you undamaged, in that same shape we manufactured them. The shrink not only protects the top like most steel companies do; the wrap protects the ends and bottom of the steel package as well. The custom-designed corners protect against forklift damage on the job site.

THE STEEL TRUTH AND NOTHING BUT THE STEEL TRUTH

- Most manufacturers and big box stores claim to provide 29 gauge steel panels, and they do just that. The problem arises when they don’t say what the actual thickness of the panel is. Steel mills are allowed to make 29 gauge steel from a range of 0.0142″ – 0.0152″ in thickness. When steel panel manufacturers, like All American Steel, order steel, they have the option of requesting 0.015″ nominal or 0.015″ minimum. Ordering 0.015″ nominal assures the panel manufacturer of getting the best price. However, they are not assured of getting the best quality, because something less than 0.015″ thickness may be shipped. The thinner the steel, the lower the price, most times significantly cheaper. All American Steel does not buy nominal. All American Steel only buys 0.015″ minimum thickness assuring a consistent quality product.

- Ask our competitors whether they buy 0.015″ nominal or 0.015″ minimum. If they don’t know you can pretty much bet they buy nominal. Our people at All American Steel know how thick our panels are, and they are darn proud of it.

THE STEEL TRUTH EQUATION

THICKER STEEL = BETTER QUALITY STEEL = ALL AMERICAN STEEL

Do you have a project coming up? Let us know what you need and we’ll be ready to help you out!

"*" indicates required fields